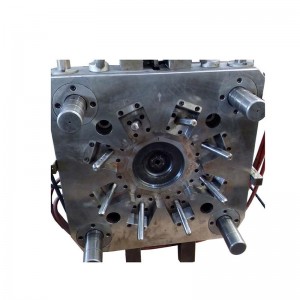

Aluminium e Tloaelehileng ea Khatello e Phahameng ea Die Casting Mold Die Cast Mold bakeng sa likarolo tsa Auto / Lebone la LED / Sesebelisoa sa Matla / Karolo ea Telecom

Litaba tsa Motheo

| Lebitso la sehlahisoa | High Pressure Die Casting Mold |

| Mold | PH13,H13, DVA, DIEVAR, 8407, 8418, W400 joalo-joalo |

| Alloy ea ho lahla | Aluminium |

| Cavity Qty | Cavity e le 'ngoe, Cavity e mengata kapa Combination Cavity |

| Tonnage | 200T-2000T |

| Kalafo | Phekolo ea Mocheso, Nitriding, polishing joalo-joalo. |

| Bophelo ba Hlobo | Lithunya tse 30000, lithunya tse 50000, lithunya tse 80000 li itšetlehile ka lihlahisoa |

| Lisebelisoa | 1. Likarolo tsa koloi; |

| 2. Mabone & likarolo mabone; | |

| 3. Likarolo tsa lisebelisoa tsa motlakase; | |

| 4. Likarolo tsa Telecom; | |

| 5. Lisebelisoa tsa liindasteri le Machine Sparepart; | |

| 6. Likarolo tsa lisebelisoa tsa ka tlung; | |

| 7. Likarolo tsa thepa ea ka tlung; | |

| Lead time | Matsatsi a 35-60 |

| Kopo e khethehileng | Ho latela kopo ea moreki |

Re feme ea Aluminium Die Casting Mold, moo o ka fumanang High Pressure Die Casting Tooling e tiisang phaello ea hau e kholo.Hangata re buisana le bareki ka lintlha tsa Pressure Die Casting Molds, ebe re etsa lisampole ho fihlela moreki a khotsofetse ke Pressure Die Casting Molds.

Re ka iketsetsa, empa eseng feela ho tsena:

Aluminium die casting auto part hlobo

Aluminium die casting telecom housing hlobo

Aluminium die casting power tools hlobo

Aluminium die casting power tools housing hlobo

Aluminium die casting auto gearbox housing hlobo

Aluminium die casting auto water pump housing hlobo

Aluminium die casting light housing hlobo

Ho kenyelletsa le lisebelisoa tse ling tsa Aluminium High Pressure Die Casting.

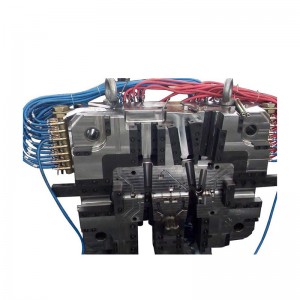

FENDA Aluminium Die Casting Mold Mekhoa ea Tlhahiso

Mehato e ka sehloohong ea mekhoa ea rona ea ho etsa hlobo ea aluminium alloy die casting ke : CNC Milling Process, Heat Treatment, EDM Process, WEDM Process, Polishing, le Assembling.

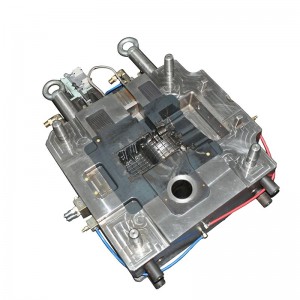

Mokhoa oa ho Milling oa CNC

Mohato oa pele oa aluminium shoe casting hlobo e etsa: sebelisa litsi tsa machining tse lebelo le phahameng ho sila mokoti oa hlobo, o siea tumello ea machining ea hoo e ka bang millimeter e le 'ngoe bakeng sa sebopeho sa sehlahisoa.Ke bakeng sa deformation e itseng ka mor'a phekolo ea mocheso.

Ka mor'a ho siloa ha pele, sekoti sa hlobo se tla romeloa bakeng sa phekolo ea mocheso.

Ha li-cavities li khutla ka mor'a phekolo ea mocheso, mochine oa bobeli o tla etsoa.Mokhoa ona re o bitsa machining a matle.Lekhetlong lena, boholo bohle bo ipapisitse le setšoantšo sa moralo oa hlobo

Mokhoa oa EDM

Ka mor'a linako tse peli tsa mechine, ho ntse ho e-na le libaka tse ling tseo ho leng thata ho li khaola ka ho itšeha ka lebelo le phahameng, joale li tla phethoa ke EDM.

Ho na le li-grooves tse ngata tse tebileng le li-slits tse moqotetsane le li-cavities tse rarahaneng holim'a hlobo, tseo ho leng thata ho li sebetsana le mechine ea ho sila.Sena se hloka mochine oa ho ntša motlakase oa EDM.

Ho phaella moo, EDM e boetse e sebelisoa ka tloaelo bakeng sa likarolo tse ling tse hlokang ka ho khetheha ho nepahala ha ts'ebetso e phahameng le ho hlaka holimo.

Mokhoa oa WEDM

Molao-motheo oa ts'ebetso oa WEDM (ho itšeha ka terata) ke ho sebelisa mohala oa tšepe o mosesaane o sa khaotseng (o bitsoang terata ea electrode) joalo ka eleketrode ho etsa pulse spark discharge holim'a workpiece ho tlosa tšepe le ho e khaola ka sebopeho.

Likoti tse ejector ka har'a hlobo, hammoho le likoti tse nang le mahlakoreng a hlabang, tse nang le sebōpeho se khethehileng tse ke keng tsa etsoa ka mochine, 'me lisebelisoa kaofela li phethoa ka ho khaola terata.

Ka mor'a ts'ebetso ena, hlobo ea hlobo e tla belisoa.'Me ts'ebetsong ea ho qetela, kopanya hlobo ea aluminium ea die casting, le ho lekoa.

Fenda Aluminium Die Casting Mold Manufacturing Molemo

Ha ho tluoa ho nts'etsopele ea hlobo ea "die casting" ea boleng bo holimo, litšusumetso tse 'maloa li kenya letsoho katlehong e akaretsang ea ts'ebetso.Fenda e fana ka lits'ebeletso tsa tlhahiso ea hlobo ea aluminium ea die casting ho latela lintlha tsa projeke ea hau.Fenda e fana ka melemo e latelang ea tšebeletso ea ho lahla lefu:

- Boenjiniere ba Sehlopha sa Pele

- Lisebelisoa tsa li-die-cast tse entsoeng ka tlung

- Laola le ho hlokomela likarolo tsohle tsa lisebelisoa

- Ho nts'etsapele litekanyetso tsa ts'ebetso ea ente: boholo ba heke, sebaka, lebelo la ho fepa, nako ea ho tlatsa, khatello ea ente, boholo ba khatiso

- Mohala oa karohano, semathi, ho khaphatseha, ho tsoa moea, ho pholisa

- Botenya ba lebota bo tlase le bo boholo

- Khetho ea thepa ea hlobo le boima bo thehiloeng ho matla a hlobo a ho bala

- Kereiti e phahameng kapa ea Premium PH13 kapa Dievar

- Ketsiso ya phallo

- Moralo, radii, lifaele

- Ho theha machining stock

- Tšebeliso ea bafani ba lisebelisoa tsa lapeng le mose ho maoatle

Boemo ba Feme

Fenda, moetsi oa lihlahisoa tsa aluminium tse thehiloeng China, ka boikhohomoso o fana ka lihlahisoa tsa boleng bo holimo indastering ea tlhahiso ea li-die casting.Ho tloha ho moralo oa lisebelisoa ho isa ho tlhahiso ea likarolo, ho etsa mochini oa CNC, ho qeta le ho paka, re fana ka litharollo tse felletseng le tse theko e tlaase bakeng sa litlhoko tsohle tsa hau tsa ho lahla aluminium.

- 1-Emisa ho nepahala ha aluminium die casting solution

- Lilemo tse 17+ tsa boiphihlelo, le basebetsi ba 140

- ISO 9001 & IATF 16949 e netefalitsoe

- 7 Mechini ea li-casing tsa die ho tloha ho 400T ho isa ho 2000T.

- 80+ litsi tsa machining tsa lebelo le holimo / tse nepahetseng haholo

- 30 lihlopha tsa phahameng-ho nepahala khohlano tšubuhlellano tjheseletsa, kalafo holim'a metsi le mechine e meng ho nepahala khethehileng

- Sete e le 'ngoe ea Zeiss CMM, 1 sete ea Eduard CMM, 1 sete ea CT ea indasteri, 1 sete ea spectrometer ea Oxford-Hitachi le lihlopha tse' maloa tsa bahlahlobi ba khase ea khase.

Ka litharollo tsa senotlolo, sehlopha sa litsebi, le boitlamo ba ho fana ka lihlahisoa le litšebeletso tsa boleng bo holimo, re u thusa ho boloka litšenyehelo le ho tsamaisa merero ea hau ka thelelo.Ikopanye le rona bakeng sa morero oa hau o latelang.